CNC VERTICAL MACHINING CENTER

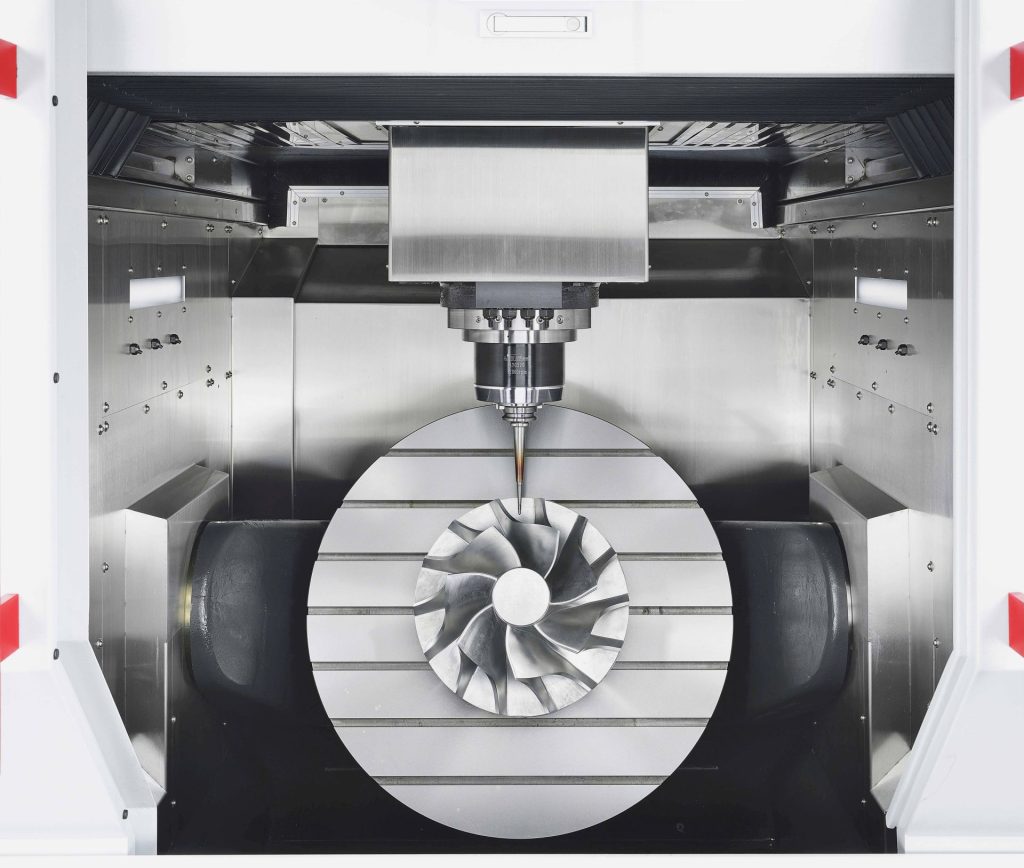

CNC vertical machining center is a type of CNC (Computer Numerical Control) machine and is a machine tool that can process many different materials such as metal, plastic, and wood. These types of machining centers place the workpiece on a fixed platform and move the cutting tool in various directions on the workpiece, creating the desired shape and dimensions.

Some features of CNC vertical machining centers may be:

- Multi-Axis Machining: They are generally capable of three, four or five axes of movement. This makes it possible to machine complex and multi-surface parts.

- Fast and Precise Machining: Thanks to CNC control, fast and precise cutting operations can be performed.

- Automation: Automated tool changing systems and workpiece handling systems can make the machining process more efficient.

- High Efficiency: CNC vertical machining centers can operate at high speeds and continuously, making them suitable for mass production.

- Various Applications: They can be used for many different applications such as metalworking, prototype production, mold making, custom parts production and more.

- CAD/CAM Integration: By integrating with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, programming and processing of complex parts is facilitated.

CNC vertical machining centers are widely used in many industrial applications such as industrial production, machinery manufacturing, automotive, aerospace, electronics and metalworking. These machines play an important role for the production of parts with complex geometries, prototypes and parts that require mass production in large quantities.