ASSEMBLY

CNC (Computer Numerical Control) assembly refers to the process of assembling machines or parts using CNC technology. CNC assembly is an important step in the production of complex parts or machines used in various industries. This process usually includes these steps:

- Preparation of Parts: Parts machined by CNC machines are first properly cleaned and inspected. Each part is checked for compliance with production specifications.

- Preparation of Assembly Instructions: Instructions are prepared for the assembly process. These instructions determine which parts are to be installed where and how. Assembly instructions often include visual instructions, diagrams, and written instructions.

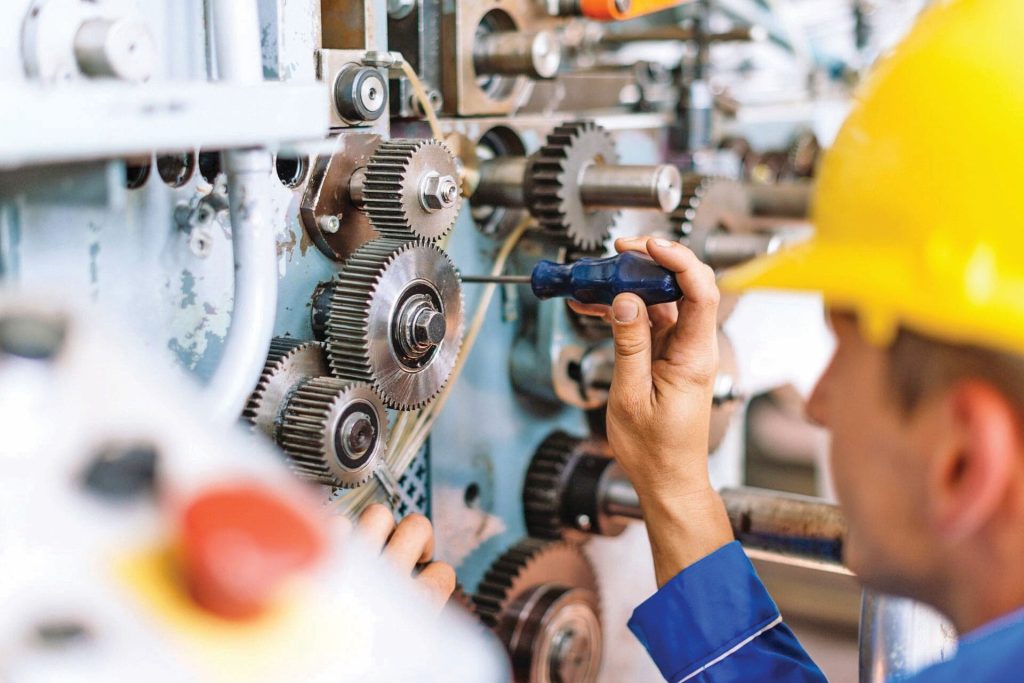

- Assembling Parts: The assembly team’s job is to assemble the CNC machined parts and assemble all the parts needed to create the machines or parts. In this process, screwing, welding, gluing and other assembly techniques may be used.

- Quality Control: Products that go through the assembly process are subject to a quality control process. Every part and assembly process is checked for compliance with established quality standards. If necessary, corrections or improvements are made.

CNC assembly requires significant expertise, especially when it comes to manufacturing complex machines or parts. Precise parts fit and correct assembly are critical to the quality and durability of the product. Therefore, it requires a meticulous process managed by experienced technicians and engineers.